Key Specifications/Special Features:

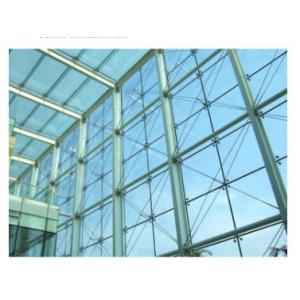

Frameless Structural Glass Curtain Wall Façade Aluminum Mullionless Spider Sealant Silicone Double Glazed Glazing System

FAMOUS Structural Glazing Systems are streamlined curtain walls of glass that are attached using silicone bonding, or anchored by means of rods, cables, glass fins or other unobtrusive ways. Glass anchorage fins or struts provide the most unobtrusive support system of all, and a continuous wall of structural glazing supported by glass fins can appear to be entirely unsupported, allowing the clean, sleek lines of the architecture to stand tall.

Glass fins or struts provide the most impressive results in structural glazing, and depending on location and installation, can be the most cost-effective system for supporting the glass curtain that is structural glazing. Other systems include steel rods or vertical cables, both of which allow for greater height of unsupported spans. These systems, however, put a greater load on the boundary structure and therefore tend to be more expensive to install.

Point-supported structural glazing, especially if using glass fins as a backup support system, is the most transparent system currently available, and it can give the impression that an entire wall is completely unsupported. This can be custom engineered to fit any space and is assembled using silicone joints between individual panes of glass. To avoid the disparity that might arise by on site application of silicone, some structural glazing can be partially pre-prepared with aluminium channels affixed by silicone to the back of panes, allowing for on-site assembly using toggles, with minimal silicone application.

Structural glazing is used with the most impact on large, commercial buildings, but has many other applications, including glass entrance-ways, skylights, canopies, and glass elevator enclosures.

FAQ:

Q: Are you trading company or manufacturer ?

A: We are large scale aluminium manufacturer located in Zhejiang Province.

Q: How long is your delivery time?

A: Generally it is 17-20 days after down payment if we have ready-made moulds.

There will be 7-10 days more if making new moulds.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we can offer the samples less than 30cm per piece by free charge and also pay the cost of freight.

Q: What is your terms of payment ?

A: T/T: 30% down payment in advance, balance before shippment.

L/C: 100% LC at sight